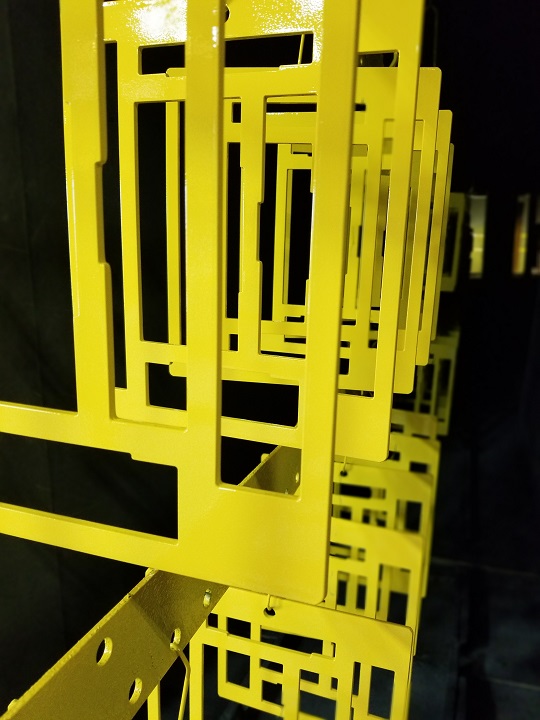

Conveyorized Powder Coating System

Performance Powder Inc. uses a customized conveyor powder coating system for superior performance and speed. In order to ensure quality and adhesion, a 6 stage pretreatment washer cleans and etches the surface of the material. Using proprietary techniques, a film thickness of 6 to 8 mils and up to three coats of powder can be achieved in one run. The system is one of the largest in Southern California. We have the capacity to handle some of the largest parts and highest volume. No matter what the project, PPI has the experienced personnel to develop custom racking solutions to maximize efficiency and minimize costs.

High throughput

By utilizing processes refined over many years, PPI is able to have extreme density on extrusions and other parts.

High Skill

With our professionally trained painters PPI can target hard to reach areas such as faraday cages to ensure full coverage on any surface.

High Standards

PPI's total quality system allows for both highly cosmetic consumer products and functionality for industrial customers. Each process is refined to ensure satisfaction.

High Yield

PPI's proprietary system allows for multiple coats. This allows for significant cost savings on primered products, castings, and hot dipped galvanized materials.